Say What You Mean and Mean What You Say

Getting There From Here

MINDS ON

The UPS Solution

For more than 100 years, UPS has been focused on finding ways to move product from one place to another as quickly, efficiently and economically as possible. In 2012, they delivered more than 4 billion packages and documents to nearly 9 million daily customers in more than 220 countries and territories. To do so, they used a fleet of more than 96,000 cars, vans, tractors and motorcycles, and 230 jets.

Watch this commercial from UPS:

Logistics is an important and complex issue. Consider the following questions:

- How do you know how much of each product to buy?

- From where do you get it?

- How do you have it shipped?

- Where do you store the excess and how much do you need to have on hand?

- How should you ship orders to your customers?

ACTION

The Global Distribution Challenge

When a company exports to a single market, it selects a dependable mode of transportation to ensure the safe arrival of a product within a reasonable time for a reasonable carrier cost. But once a company becomes global, such a solution to the movement of products could prove inefficient and costly.

Consider Ford’s logistical challenge in manufacturing the Ford Escort in Europe. Final assembly takes place in the UK and Germany, but parts are manufactured in many other countries.

carCountries3

Logistics and the Supply Chain

Logistics is the process of strategically managing the sourcing, movement, and storage of materials, parts and finished inventory (and the related information flows) through the organization and its marketing channels. The goal for logistics is to maximize current and future profitability through the cost-effective fulfillment of orders.

The Supply Chain is the sum total of all the activities involved in moving raw materials, processed goods, and finished products into an organization, and moving the semi-processed or finished goods out of the organization toward the end consumer.

Vertical Integration is when a business owns most or all of its supply chain, from the acquisition of raw materials to retailing.

Horizontal Integration is when a business expands its operations by acquiring its competitors.

There are four basic components in the Supply Chain:

- Sourcing - dependable suppliers for raw materials, machines, technologies, manufactured components, etc.

- Warehousing & Storage - storing or products and movement of them.

- Information Management - tracking the movement of the product via electronic data interchange (e.g., Just in Time Inventory Management).

- Physical Distribution - the activities required to move/transfer the good from the producer to the consumer

1. Sourcing

When choosing sources of materials and parts, there are numerous considerations:

- Should multiple suppliers be used or just one?

- What are the transportation costs?

- How long will it take to arrive?

- Are goods available locally or not?

- What kind of assurance do we have of the quality of the raw materials and parts?

- What back up plans are in place to deal with disruptions in delivery service?

- Can we create economies of scale by ordering larger quantities?

When sourcing across borders, businesses need to be aware of the numerous “added costs” (26-105% on top of the listed price):

- International freight, insurance and packing (10-12% additional cost);

- Import duties (0-50%);

- Customhouse brokers

fees (3-5%); - Transit or pipeline inventory

(5-15%); - Cost of letter of credit

(1%); - International travel and communication costs (2-8%);

- Company import specialists

(5%); - Redesign of goods to meet required specifications (0-15%).

2. Warehousing and Storage

Businesses need to decide how much inventory to have on hand. Having excess inventory on hand allows a business to meet changes in demand easily, but it means that much of its cash is tied up in inventory. Storing inventory also costs money.

A business either needs to rent warehouse space or buy a building to store the inventory. If the building is owned, it means that much of the business’ cash is tied up in the building, and in expenses such as property taxes and utilities.

3. Inventory Management

Retailers use a point-of-sale system to assign each stock-keeping unit (SKU) a code or stock number, designed to organize and track sales of goods.

Companies are often reluctant to take on and store too much inventory because this takes up valuable space and increases the danger of damage or theft. Thus, each link in the supply chain tries to pass the goods on as quickly as possible.

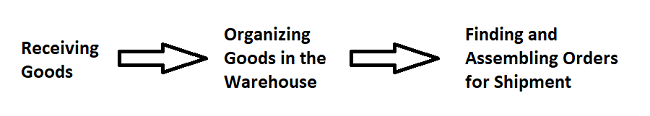

The Warehouse Process

The more efficient the warehouse is in moving through this process, the less the cost will be per unit.

Just-in-Time (JIT) Inventory Systems are designed to eliminate storage altogether.

This system, popularized by Toyota, requires suppliers to make and ship materials required by the factory or retailer efficiently so that the goods arrive at the factory floor, retail store, or workstation exactly when they are needed. Watch this video to see how it work:

4. Physical Distribution

This is the actual movement of the products from the business to the customer. If the business is in the middle of the supply chain, it will be concerned not only about getting goods to the customer, but also about receiving the goods. This can be a complicated and frustrating process, especially across international borders.

Many factors affect the type of transportation that will be used for physical distribution:

- Topography (this is an area’s natural and artificial physical features)

- Climate

- Cost

- The type of product being shipped

- The destination.

Comparing Challenges

Comparing Challenges

Watch these two videos, which highlight some of the factors affecting distribution in Canada and the U.S.

Now, use a Venn Diagram to compare and contrast the distributed challenges faced by Canada and the U.S.

Modes of Transportation

There are a number of ways that materials, parts and finished inventory are transported. The interactive below will allow you to see some of the advantages and disadvantages of each:

modes

Containerization

Containerization is a system of intermodal freight/cargo transport using standard ISO containers (known as Shipping Containers or Isotainers). These ISO containers can be loaded and sealed intact onto container ships, railroad cars, planes, and trucks.

Containerization is also the term given to the process of determining the best carton, box or pallet to be used to ship a single item or number of items. Approximately 90% of non-bulk cargo worldwide moves by containers stacked on transport ships.

Watch this video to see how this simple concept revolutionized the way products are shipped, thus greatly increasing the opportunities for international trade:

https://youtu.be/Gn7IoT_WSRA

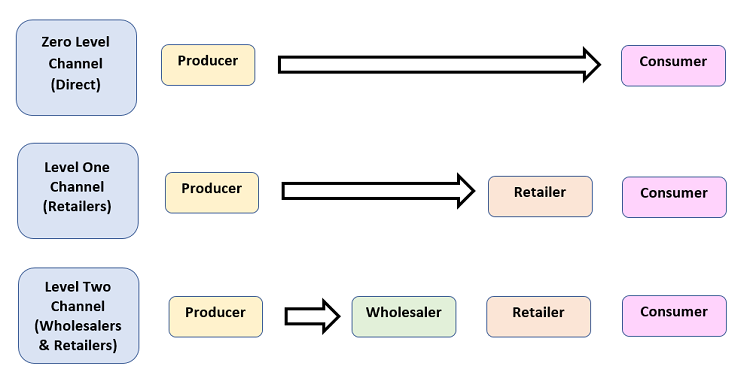

Channels of Distribution

A Channel of Distribution is the chain of different parties that a product flows through in moving from the producer to the end consumer; it is essentially the distribution part of the Supply Chain. Watch this video for an overview of the different types of distribution channels:

A company may have more than one distribution channel within their Supply Chain, with one or more intermediaries within it. In addition to wholesalers and retailers, other intermediaries may include distributors and agents. Similar to wholesalers, a distributor buys product, stores it, and sells it for a profit. However distributors align themselves with certain companies (e.g,. a Coke distributor will not stock Pepsi products) and thus have a closer relationship with their suppliers. Agents or Brokers represents the manufacturer or retailer in selling or purchasing a product. They take possession of the product but do not own it; they make their profits through commissions or fees.

Distribution Channel

Distribution Channel

Choose a single Canadian product and research its distribution channels.

Create a diagram showing the channels the product travels through when marketing the product:

- Within the city it’s manufactured in;

- Across Canada;

- Globally.

Costing

Each level of the supply chain adds new costs to the product. A distributor or retailer must figure out the full landed cost of the product when determining a suggested retail price for the product. The fully landed cost is the original price of the product plus all transportation fees, currency conversion, customs, tariffs/duties, taxes, insurance, and handling fees.

Follow this scenario to see how landed cost is calculated:

Imagine that you are a purchasing agent acting on behalf of a Canadian retail chain that wants a new and interesting line of preserves for its upscale customers. You visit a trade show in France to look for suitable European suppliers. You see a booth displaying dozens of different jams, jellies and compotes that are not available in Canada - exactly what your client is looking for. The price of each jar of jam is marked at 1.50 euros.

But you can’t just take that 1.50, convert it to Canadian dollars, and apply a markup to determine a selling price. You will need to take into account the transportation and shipping costs, insurance for the goods in transit, handling fees (those jars may require extra packing procedures), and customs, tariffs, and taxes on our end, before applying your markup (not to mention your own commission as an agent, which is based on the value of the goods shipped). Calculating landed cost is a complicated procedure.

Watch this video which summarizes the factors that go into calculating landed cost:

CONSOLIDATION

Amazon’s Distribution Magic

Watch this video, which outlines how the e-commerce giant runs their complex distribution network:

Resources:

- “UPS Logistics as Masterpiece of Streamlined Supply Chain Management.” from Supply Chain 24/7, August 20, 2013.